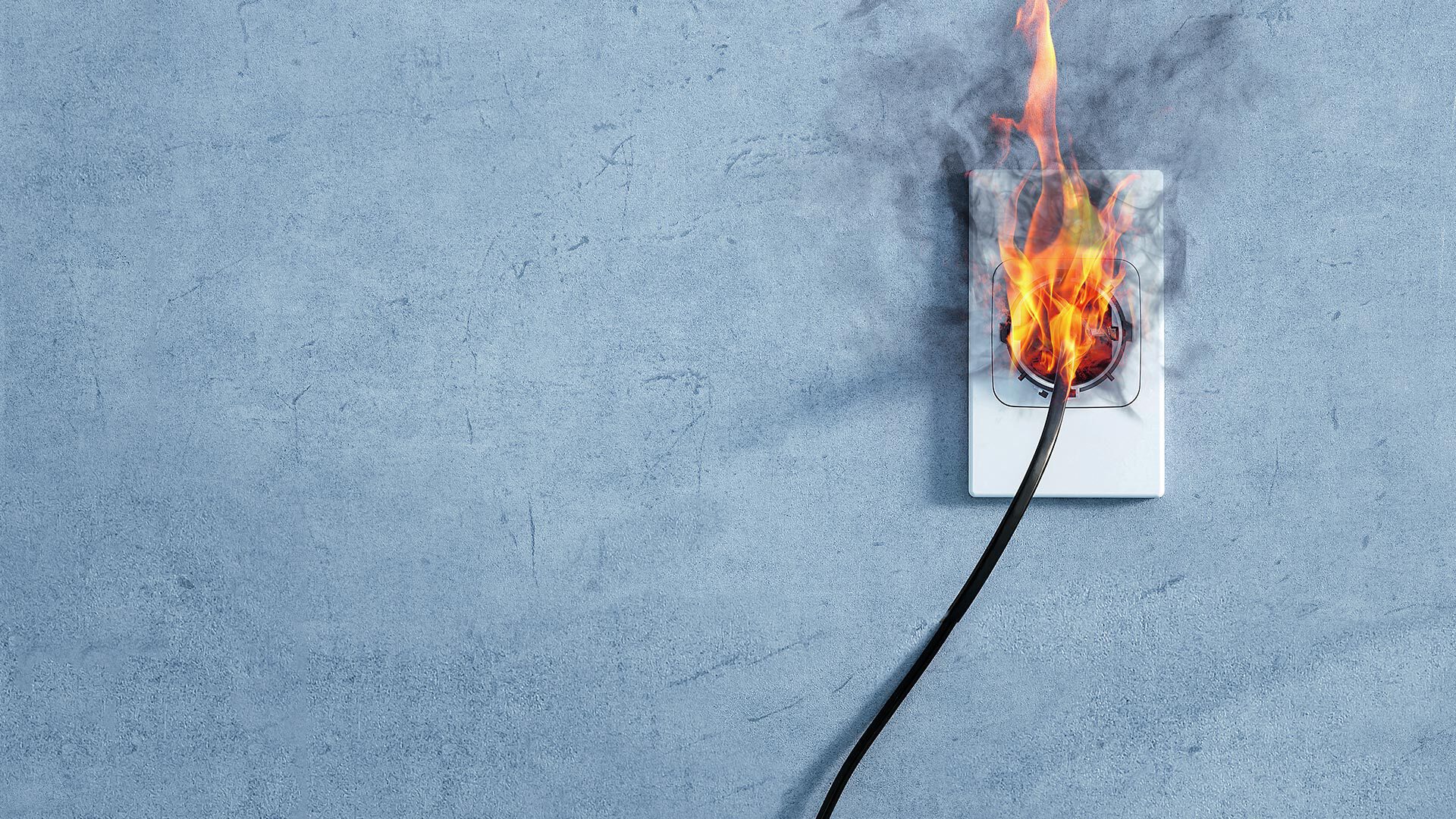

Electrical safety is an important basic requirement under which technology products are approved for the market. It is therefore an integral part of the regulatory tests for certification and the associated market approval.

Testing and verification of product safety is one of the basic requirements that your product must meet if you want to market it. Current standards specify not only the electrotechnical design, but also important requirements to prove conformity in terms of mechanical stress tests, as well as heat resistance. IEC/EN standards define the European standards. In addition, the CB program provides a global solution for market access in currently over 50 international countries. NRTL/UL certification is required for the US and Canadian markets.

The risk from hazards posed by equipment should be kept to a minimum for people, animals and property. To achieve this, certain safety standards must be met.

To ensure electrical safety, both standard normal operation and fault operation of electrical equipment are subject to various requirements – harmonized throughout the EU by the Low Voltage Directive 2014/35/EU, which must always be complied with.

The corresponding protective measures must be effective at all times so that no hazards arise during the entire service life of the device. This does not necessarily have to be tested according to a standard, as long as the person placing the device on the market complies with the EU directive. However, we recommend applying the harmonized standards that relate to the directive.

Examples of the protective measures are protection against direct contact by insulation (e.g. of power cables) and against indirect contact with the aid of conductive systems or housing parts.

Electrical safety is subject to different certification regimes: While NRTL (Nationally Recognized Testing Laboratory) approval covers regulatory testing for the U.S. and Canadian regions, the so-called CB (Certified Body) Scheme is an international system dealing with the safety of electrical and electronic components, devices and products. The latter serves the mutual recognition of test reports and certificates among the approximately 50 participating countries.

The Low Voltage Directive 2014/35/EU applies to electrical equipment with a rated voltage of 50 to 1,000 V (AC) or 75 to 1,500 V (DC). It covers all safety objectives of the equipment, including possible mechanical hazards. Therefore, with some exceptions, non-electrical hazards must also be considered.

The standard DIN EN 62368-1 Equipment for audio/video, information and communication technology – Part 1: Safety requirements is a product safety standard that defines

Introduced in 2021, EN 62368-1 covers the scope of over 40% of all existing Certified Body schemes, as well as some earlier standards.

Depending on the approval objective of the devices to be tested, various test scenarios are run through. Regardless of the approval regime, the necessary electrical safety tests can be divided into the following areas, among others:

The low-resistance continuity through the protective conductor is measured. Even a high protective conductor resistance for a short time indicates an interruption of the protective conductor or a fault in a protective conductor path.

Here, the possible flow of a harmful current through the human body is tested, if necessary, also through the protective conductor resistance.

These tests are used to verify the insulation resistance of electronic components in the low-voltage range (protection classes I and II).

In a so-called climatic chamber, the devices are tested for their reactions at extreme temperatures.

According to the specifications, the robustness of the DUT with respect to the mechanical load is checked as part of the performance measurement.

The European part for electrical safety is defined by the associated EN/IEC standards. We are accredited by the German Accreditation Body (DAkkS) to perform regulatory tests of electrical safety according to the following norms and standards, and thus to accompany you on the way to market approval:

In addition, we offer further product testing for electrical safety

for other non-European target markets. For example, we offer accredited testing in accordance with the requirements of the CB program, as well as NRTL/UL certification for approval for the US and Canadian markets.

In this way, we guarantee you rapid completion of the regulatory tests for electrical safety as part of the market approval from a single source.

Our laboratory in Essen is accredited, by the DAkkS according to DIN ISO 17025 to perform a wide range of electrical safety tests.

Please refer to our accreditation overview for detailed information on our lab’s accreditation services in Germany.

Electrical safety prevents dangers posed by electric currents and their effect on the human body – an electric shock is the worst case scenario, which even small electrical appliances can cause. This makes electrical safety a basic requirement for the market approval of electronic devices.

In general, each certification regime uses its own standards to test the electrical safety of technical devices. For this reason, it is crucial to learn about the respective requirements.

The following information, among others, is required to select the appropriate test or tests:

A complete list with the following content is also required:

The following additional information will help to ensure a smooth process:

The main difference is the regional availability of the two approval systems NRTL and CB scheme: Products tested by NRTL-certified laboratories are approved for the US and Canadian markets. The CB scheme, on the other hand, is a multilateral agreement that emerged from the European Commission for Conformity Testing of Electrical Equipment (CEE). Certified products may be traded in the markets of the member states of the International Commission on the Rules for the Approval of Electrical Equipment (IECEE).

The 1500 V are assumed as the transient voltage from external circuits.

| Cable type | Additional requirements | Transient voltages |

|---|---|---|

| Conductors arranged in pairsª – shielded or unshielded | The building or structure may have but does require potential equalization. | 1500 V 10/700 μs

Only differential, if a conductor in the device is connected to earth |

Important: This requirement only applies to interfaces that are not in-house interfaces.

AV equipment must meet the requirements of the EN 62368-1, which also includes moving parts in chapter 8 (mechanics). Fans are classified accordingly and safeguards are required. The Machinery Directive is therefore not necessarily used for approval purposes.

The CB scheme simplifies access to numerous markets by avoiding duplicate testing. It can be a difficult, time-consuming and expensive process to obtain the necessary international certifications for market access. The CB scheme created by the IECEE (International Electrotechnical Commission for Electrical Equipment) allows for faster and easier access to global markets. This process allows for the mutual recognition of test results among participating countries. Usually, no additional tests are required. A CB test report from a CBTL (CB Testing Laboratory) and a corresponding CB Certificate from an NCB will help you meet various international safety requirements and gain market access in over 50 countries.

A data sheet and a certificate are required if batteries are installed in the device. The installed batteries are then tested for compliance with the EN 62368-1 and checked whether it is possible to overcharge the batteries. The battery is shorted, charged with reversed poles (if possible) and faults are produced in the charging and discharging circuit.

Only one change was made to the EN 62368-1:2014, AC:2015 to EN 62368-1:2014 and AC:2015+A11:2017: The Italian variation in Section F.1 was deleted in Annex ZC.

No, not necessarily. However, a risk assessment must be made to determine whether the FW update will affect the existing conformity declaration. The DoC (Declaration of Conformity) must also be completed for the new SW/HW combination. The risk analysis will determine whether new tests are required.

The 2020 version is only available in the IEC version. The Committee has rejected a harmonization, which means that this version will not be written into European law. So the EN 62368-1:2014 + AC:2015 + A11:2017 is currently the valid version for EN.

The Low Voltage Directive only applies to voltages exceeding 75 V DC. The Low Voltage Directive automatically applies if your device falls under the RED Directive (voltage limits are reduced to 0 V.). If the RED does not apply to your device, the Low Voltage Directive will not, in fact, apply to your device either. However, the Product Safety Act will apply, which stipulates that unsafe devices must not be put on the market. As the manufacturer, you can either guarantee the safety yourself (not recommended) or you can still test your product according to the Low Voltage Directive. We recommend that you test your device according to the Low Voltage Directive to prove compliance with the Low Voltage Directive in your manufacturer’s conformity declaration with a valid test report.

The LVD does not cover battery-powered flashlights. The Product Safety Act applies, which stipulates that unsafe devices must not be put on the market. You should install only certified batteries. If you are not sure whether you are complying with the Product Safety Act, we would still recommend testing the device according to the LVD. However, the EN 62368-1 does not apply in this case.

Unfortunately, there is no checklist available. We recommend buying the standard and then to address the safety aspects. Every device is unique, and so are the safeguards. There is no-one-size-fits-all application.

There are no known comparable standards to the 62368-1. However, industries may require compliance with other safety standards that are not mandatory for certification (CB Scheme, NRTL Scheme or UL Certification, to name a few).

In essence, this requirement is also part of the RED (Radio Equipment Directive) under the item “Health” but may also be subject to the LVD, depending on the circumstances. First, you have to distinguish between body-worn devices with radio interfaces and devices that are not worn on the body. Body-worn means that a device is more or less permanently worn or used within 20 cm from the body. It is then about the output power (radiated) for devices with low transmission power

In general: Health protection (RED 3.1a) can be ensured through different evaluation/testing methods depending on the type of device:

The Directive does not distinguish between end-users. This will be the case in the 62368 inly. The safety assessment considers the user who will be working with the device and whether it is safe for that user to operate the device. For the time being, the documentation is the same for all users. It may be written in a different way for the inexperienced user than for the professional user, but this is not mandatory.

The safeguards vary according to the user. Depending on the device, safety instructions can be omitted if it is obvious to a skilled person. However, it is also true that increased safety risks are unacceptable, even for skilled workers.

This standard has a completely new approach; all tests must be performed for the device. The EN 62368-1 6 accepts the 60950-22, which does not require re-testing.

Yes, because the Bluetooth interface turns the product into a radio device, so it also has to be re-certified according to 62368-1.

The LVD does not apply in this case. The Product Safety Act applies, which stipulates that unsafe devices must not be put on the market. As the manufacturer, you can either guarantee the safety yourself (not recommended) or you can still test your product according to the Low Voltage Directive. We recommend that you test your device according to the Low Voltage Directive to prove compliance with the Low Voltage Directive in your manufacturer’s conformity declaration with a valid test report.

The biggest advantage is, of course, the cost factor. The device might, for example, incorporate power supply units, transformers, VDRs or similar. In that case, they will only be tested for their range of application according to 62368-1. Safety-relevant components must be certified according to certain standards. Otherwise, these components would have to be tested separately.

Generally, it is not necessary to test the integrated component parts directly. However, it would definitely be sensible to comply with the LVD requirements for end devices. This applies, for example, to the temperature application range as the motherboard and its component parts are tested together with the end device. A pre-test can therefore be performed, but it is not a “must” as the board cannot operate on its own. A pre-tested motherboard will certainly save costs for the end product to be tested.

The requirements are the same as for other components, plus everything that has to do with the fan’s rotation.

The device’s voltage and current ratings apply under any circumstances and status, as these are the normal operating conditions. The ratings are listed to prevent a device from operating, for example, with 110 V. Fault conditions are not considered in this case.

These modules must be certified according to 62368-1 if they are newly manufactured or brought onto the market after December 2020.

For a list of DIN standards, please go to https://eur-lex.europa.eu/legal-content/DE/TXT/?uri=CELEX%3A52014XC0516%2805%29

No, they are not subject to the Low Voltage Directive as they are not actively powered.

No, that is not permitted. The RED Directive will sooner or later refer to the 62368, as the 60950-1 will no longer be in effect as of December 2020.

Aviation equipment does not fall under the Low Voltage Directive but must meet aviation requirements.

Yes, a device can pass the EN 62368 and not meet the requirements of the CB scheme, although this is rather unlikely.

The IEC 62368-1: 2018 has not yet been harmonized in the EU. The 2017 version is the relevant standard for the time being.

Are you interested in more details on this topic? Are you looking for answers to urgent questions?

Please feel free to write to us. Our experts will support you with all the challenges related to the market approval of your products.