Propagation tests for lithium-ion batteries

What is meant by a propagation?

If a cell within a battery pack enters a thermal runaway (TR) – meaning it self-heats without any external energy being supplied – the thermal coupling to a neighboring cell can cause that neighbor to heat up as well and also enter a thermal runaway.

Under unfavorable conditions this can propagate through the entire cell string, i.e., cell after cell enters thermal runaway and the whole battery system propagates. This can then lead to the complete ignition of the battery or even an explosion.

How does a cell enter thermal runaway?

Modern lithium-ion batteries can be regarded as very safe. Battery systems currently on the market typically pass numerous safety tests before being released. Almost all battery systems are equipped with a so-called battery management system (BMS) that ensures safe operation.

Such a BMS monitors individual cell voltages, cell temperatures, charge currents, and other important parameters and thus ensures that cells are not overcharged or operated outside their approved temperature window. However, there are also cell faults that cannot be controlled from the outside. One example is the formation of so-called dendrites.

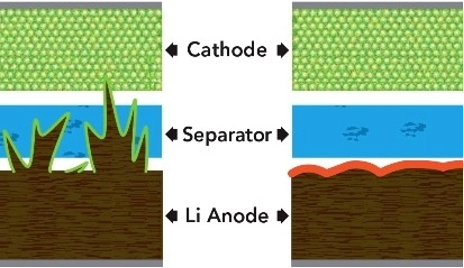

In cell aging small peaks form on the lithium anode over the years. These can penetrate the separator between anode and cathode and thus create a short-circuit path, which can lead to an exothermic reaction of the cell that can no longer be prevented from the outside.

This can then lead to thermal runaway in a cell that propagates through a whole cell string. Other scenarios are conceivable as well, for example welding beads that get between two cells during manufacturing and could cause a short circuit by friction.

Why are propagation tests so important?

For the safe operation of lithium energy storage systems, it is important to know how a storage system behaves when a cell fails, or how propagation can be prevented. By using various thermally insulating materials between cells, for example, it is possible to prevent propagation or at least slow and contain it so that no fire occurs outside the storage enclosure or so that there is no explosion but instead a controlled venting.

The functionality of such materials or measures can be demonstrated by a propagation test. Propagation tests also help during development to select and improve the right materials or measures. Even if, for several reasons, it is not possible to prevent propagation, such tests can provide insights into the course of a storage system’s propagation. From this, safety measures for the future installation site and handling can be derived.

Safety requirements for batteries

Different standards require different criteria — for example, a warning of impending propagation, the absolute prevention of possible propagation, or simply the prevention of an explosion.

- ECE R 100 (vehicle batteries), for example, requires that passengers be warned 5 minutes before a possible propagation.

- IEC 62619 (stationary storage) requires either no fire outside the enclosure or in an area around the storage to be specified by the manufacturer.

Only through propagation tests can knowledge be generated about how a storage system would behave in a worst-case scenario.

How are propagation tests conducted?

In a propagation test a so-called trigger cell must be driven into thermal runaway. Various methods are currently used for this. The methodology should simulate an internal short circuit in the cell as realistically as possible and should not further influence the test. This is where the greatest difficulties lie.

Overcharging

The simplest method is overcharging a single cell until TR. However, this delivers significantly more energy at the onset of TR than would typically occur in reality, and the TR can therefore be much more violent than it would in practice.

In addition, heavier-gauge leads must be brought into the battery enclosure, which could allow flames or smoke to escape through these openings. There are also cells with their own overcharge protection (CID) that cannot be driven into TR by overcharging at all.

Nail penetration

Driving a nail into a cell is one of the most reliable methods to trigger TR. The problem is that the apparatus driving the nail must be strong enough to penetrate the battery casing.

Alternatively, a hole in the enclosure can be provided for the nail to enter, but flames or gases can then also escape from that opening and could ignite externally from sparks.

Laser irradiation

Some standards propose irradiating a cell with a laser. While this may be a safe method to induce TR, in practice it is often difficult to conduct (due to the mechanical construction of the enclosure, etc.). In addition, such a laser is a high-cost factor.

Heating

The currently most used initiation method is heating a cell. A small heating foil is attached to the trigger cell and heated at a constant rate — typically between 5 and 10 K/s — at maximum power.

By operating the heating foil at high voltage (well above 400 V) one can achieve remarkably high heating power with a low current. This allows the use of smaller-gauge leads, which are much easier to introduce into a battery system.

What needs to be considered?

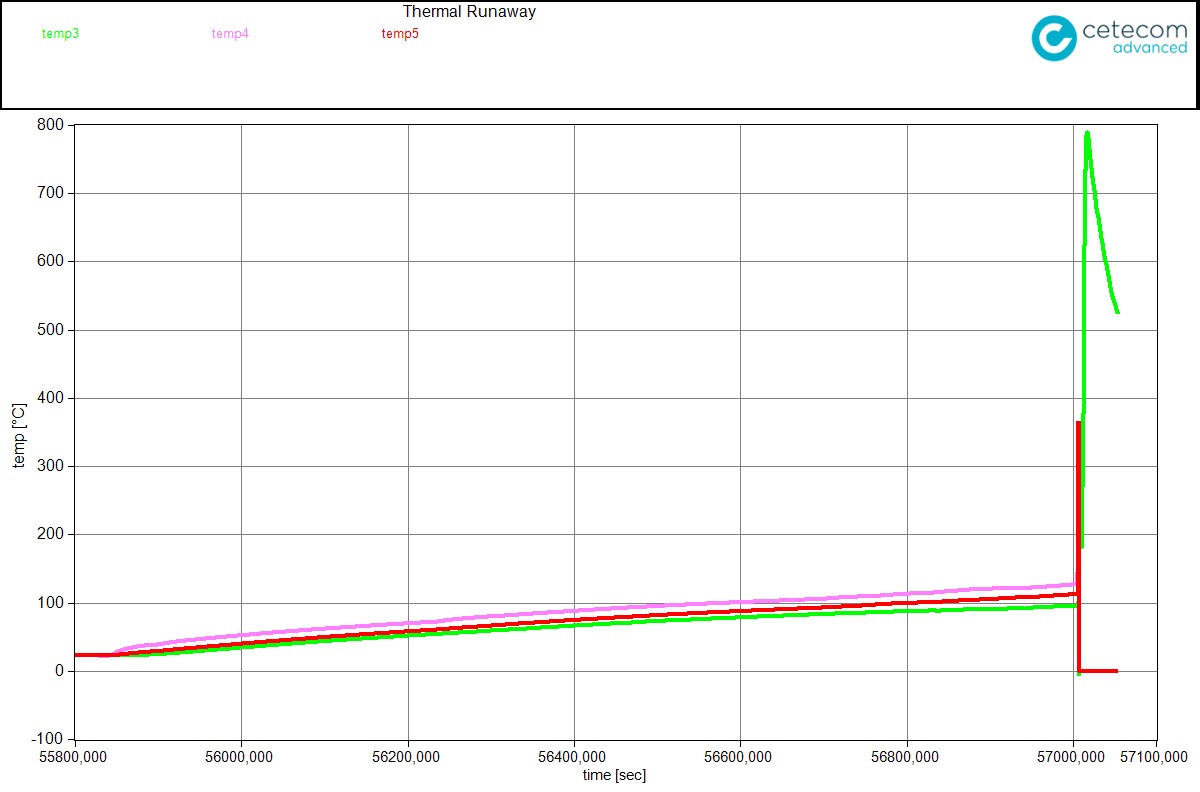

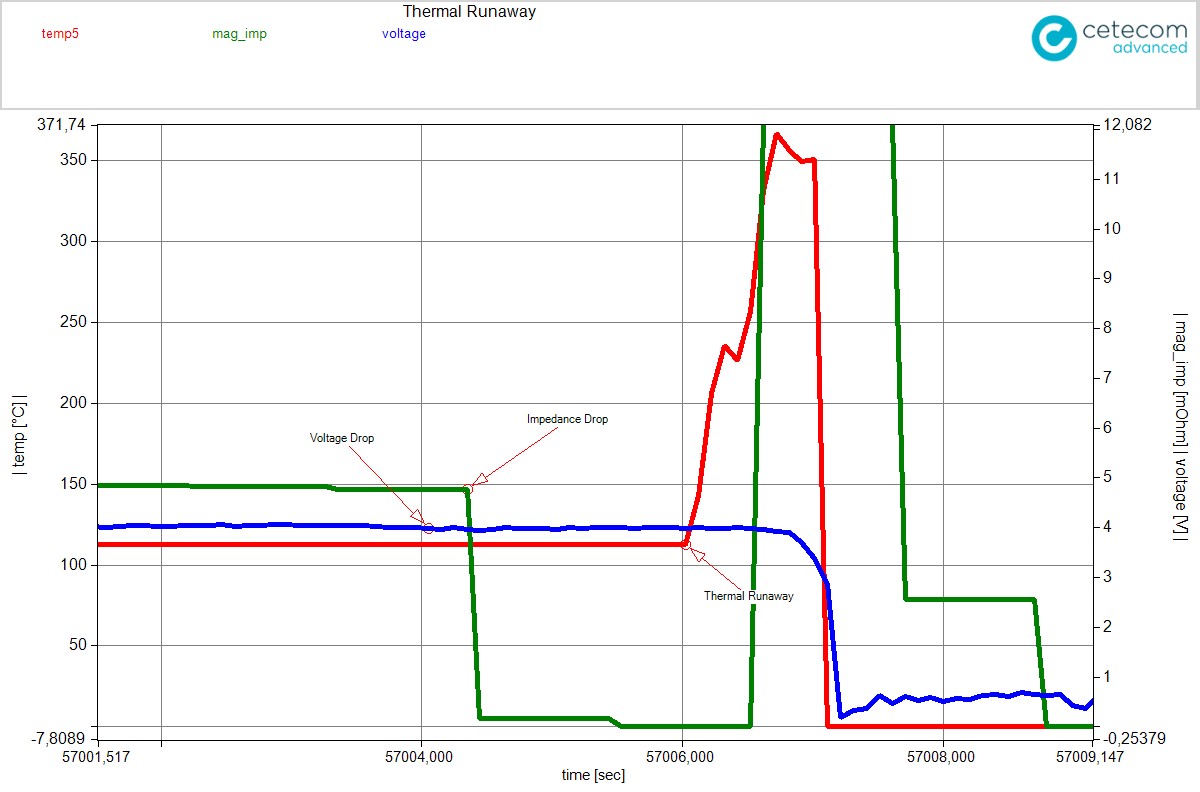

One difficulty is detecting the onset of TR. From that moment on, no further energy should be introduced into the system. Generally, a voltage drop of the trigger cell and/or an increase in the heating rate (K/s) is used as a detection criterion.

Another method for early detection is impedance spectroscopy. With this technique a sudden change in impedance is detectable as soon as an internal short circuit occurs between two layers of a wound cell. This internal “short-circuit current” should then lead to self-heating of the cell.

The propagation test stand currently developed internally by cetecom advanced allows an adjustable heating rate and uses all three possibilities to detect a separator breach:

- Increase in heating rate

- Voltage drop and

- Impedance.

The system is configurable so that any external energy input by overcharging or heating is stopped within 200 ms as soon as one of the criteria — or a combination of the three — is detected.

This ensures that in propagation tests the trigger cell is internally damaged in a safe and reproducible way. No further energy is added, achieving a test execution that is significantly closer to reality, since the cell is not over-stressed and thus the overall system does not react unrealistically violently, which would otherwise lead to “over-testing.”